Difference Between Track Roller and Carrier for Excavator and Bulldozer in Track Equipment

In the undercarriage system of tracked heavy equipment such as excavators and bulldozers, both track rollers and carrier rollers are essential components. Although they appear similar and both operate in the track link system for some parts, functions, positions, and roles are different. Knowing these differences is important for maintenance, performance optimization, and extending machine’s life.

The track roller, often called the bottom roller or lower roller, is located along the lower part of the undercarriage. Its primary role is to support the machine’s weight and guide the track chain as it moves around the undercarriage frame while the machine travels forward or backward. Because track rollers keep carry the heavy load of the machine and endure continuous contact with the ground with track link plates, they can withstand high pressure, impact, and abrasive conditions. Track rollers help to maintain track tension and ensure smooth rolling, which contributes the machine stability and efficient power transfer from the drive sprocket to the ground.

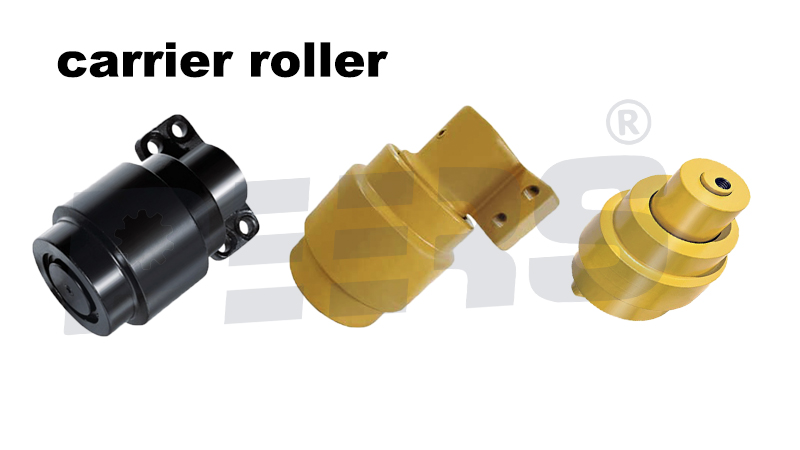

On the other hand, carrier rollers, sometimes called top rollers or upper roller, are located on the upper section of the undercarriage frame. They support the return section of the track chain as it travels from the rear idler to the front drive sprocket. Different with rack rollers, carrier rollers do not bear the full weight of the machine. Their main function is holding the track chain on the top and prevent excessive sagging, so reducing wear and vibration and helping to maintain alignment and track tension. By guiding the upper track links, carrier rollers contribute to smoother operation and reduce pressure on other undercarriage Parts, such as track links, track pins, and track bushings.

The functional difference between track roller and carrier roller leads to distinct design characteristics. Track rollers usually are larger, heavier, and more stronger. They often contain heavy-duty seals, cooper bushes, and lubrication systems because they operate close to the ground that dirt, mud, and debris can easily enter. High-impact resistance and reinforced construction are good for track rollers due to the intense load and shock forces they encounter.

Carrier rollers are lighter and smaller because they carry less load on the machine. They mainly handle the return track’s weight rather than the entire machine. Even they can endure abrasive conditions, but they do not experience the same degree of impact and pressure as bottom rollers. Carrier rollers are designed for smooth rotation to minimize friction and heat generation so track equipment can move rapidly during operation.

When it comes to wear and maintenance, track rollers often wear faster due to their heavy-duty working role. Wear patterns often result from improper track tension, uneven ground conditions, or poor lubrication when they use the excavators or bulldozers. Termly inspection for flat spots, uneven wear, or oil leakage is necessary in case pay more on repairing. Carrier rollers also require regular inspection, but broken-down in a carrier roller usually affects track chain alignment or tension before causing large-scare damage.

The key differences between track rollers and carrier rollers lie in their location, function, load capacity, and design. Track rollers operate on the lower part of the undercarriage to support machine weight and moving, and carrier rollers manage the upper return of the track chain, aiding tension and reducing vibration. Understanding and maintenance of these components ensure enhanced performance, reduced downtime, and longer service life for excavators and bulldozers in demanding work environments.