Advancing Performance: Oil track Chains VS Grease track Chains for Bulldozers

In the rugged and demanding world of construction and heavy machinery, bulldozers stand out as workhorses. These powerful machines rely heavily on their drive chains to transmit power efficiently and endure harsh conditions. Traditionally, grease chains have been the standard choice for lubricating these vital components. However, recent advancements have highlighted the superiority of oil chains over grease chains, revolutionizing maintenance practices and enhancing bulldozer performance.

The Fundamentals of track Chain Lubrication

Track links in bulldozers are subjected to extreme forces, abrasive materials, and fluctuating temperatures. Proper lubrication is crucial to minimize friction, prevent wear, and extend the lifespan of the chain. Grease and oil are the two primary types of lubricants used, each with distinct characteristics.

Grease Chains: Grease is a semi-solid lubricant that adheres well to surfaces, providing a thick protective layer. Grease chains have been favored for their ability to stay in place, even under high loads and in harsh environments. However, grease has limitations in terms of penetration and continuous lubrication, especially in high-speed applications.

Oil Chains: Oil, in contrast, is a fluid lubricant that can flow and penetrate more effectively. Oil chains are designed to deliver continuous lubrication, reducing friction and heat generation. Recent advancements in oil track chain technology have made them a more viable and often superior alternative to grease chains for dozer.

Advantages of Oil track Chains Over Grease track Chains as below aspect:

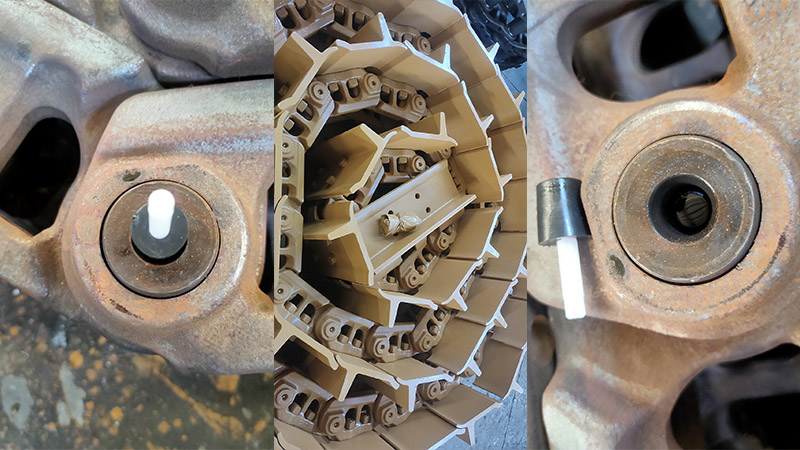

First: Enhanced Lubrication and Penetration: Oil chains excel in delivering lubrication to all parts of the chain, including the inner pins and bushings. This comprehensive coverage ensures that friction is minimized throughout the entire chain, reducing wear and tear significantly. In contrast, grease may not penetrate as effectively, leaving some parts less protected.

Second: Reduced Friction and Heat: Continuous lubrication provided by oil chains leads to lower friction levels. Reduced friction means less heat generation, which is crucial for maintaining the integrity of the chain and other components. Overheating can lead to premature failure of parts, a common issue with grease chains in high-demand applications.

Third: Cleaner Operation: Grease tends to attract and hold onto dirt, dust, and debris, forming abrasive compounds that can accelerate wear. Oil, on the other hand, washes away contaminants more effectively, maintaining a cleaner operating environment. This cleanliness translates to longer chain life and reduced maintenance frequency.

Four: Improved Efficiency: The superior lubrication of oil chains results in smoother operation, which translates to better fuel efficiency and overall performance of the bulldozer. The engine and transmission systems do not have to work as hard to overcome frictional losses, leading to more efficient power transmission.

Five: Lower Maintenance Requirements: Oil chains often come with automated lubrication systems that ensure consistent oil delivery without the need for manual intervention. This automation reduces the downtime associated with manual greasing, allowing for more continuous operation and less frequent maintenance checks.

Six: Environmental Considerations: Modern oil chains are designed with environmentally friendly lubricants that are biodegradable and less harmful to the ecosystem. In contrast, grease can be more challenging to manage in terms of disposal and environmental impact.

Real-World Applications and Feedback

Construction companies and equipment operators who have transitioned to oil chains report significant improvements in their bulldozer operations. Reduced maintenance costs, extended chain life, and better overall performance are common themes in their feedback. The initial investment in oil chain systems is often offset by the long-term savings and operational benefits.

Conclusion

The evolution from grease chains to oil chains represents a significant advancement in bulldozer maintenance and performance. Oil chains offer superior lubrication, reduced friction, cleaner operation, improved efficiency, and lower maintenance requirements. As the construction industry continues to seek ways to enhance productivity and reduce operational costs, the adoption of oil chains is poised to become the new standard for bulldozer track chains.

In the demanding environment of construction, where every component's performance and reliability matter, oil track chains provide a compelling solution that aligns with the industry's goals of efficiency, sustainability, and cost-effectiveness.